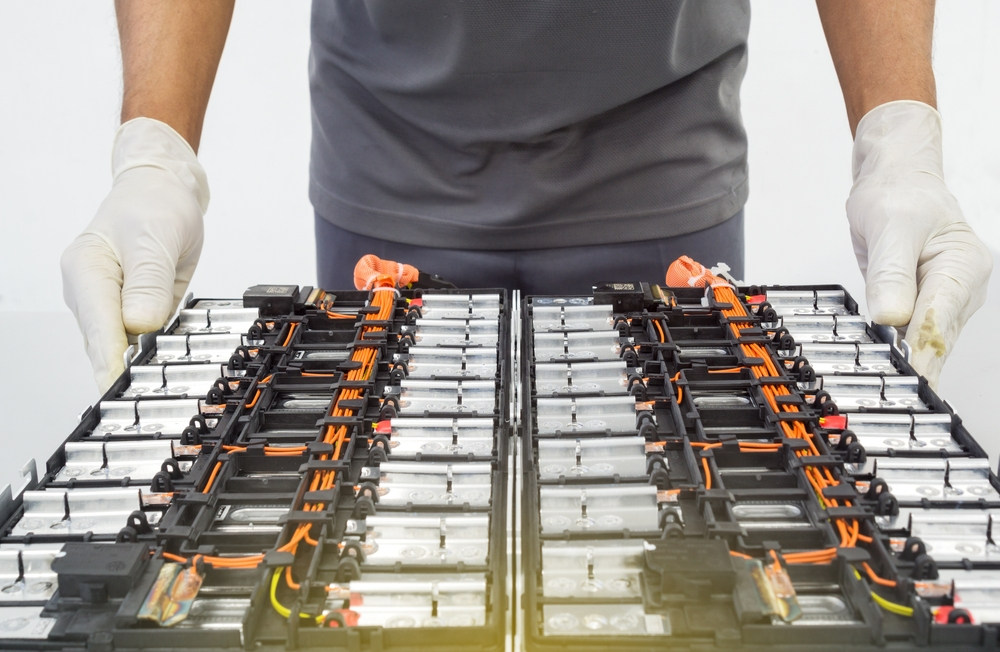

Electrive reports that the process keeps the materials in their original form, thus it does not produce black mass, enabling affordable recycling for both the anode and the cathode of the battery.

The recovered materials, as per experts at 24M, are cleaned and subject to re-lithiation to restore their original capacity. Traditional battery recycling implies first dismantling the cell itself, separating the plastic, metal, cathode and anode, with the resulted black mass being broken into its original chemical form and reintegrated into new batteries.

Direct battery recycling doesn't split the cathode and the anode, meaning that the energy-intensive splitting processes are skipped, resulting in a lower carbon footprint.

24M CEO Naoki Ota said that "better battery recycling is essential for a sustainable energy future, but the use of binders in conventional cell production has made direct recycling impractical."

"Liforever solves these challenges by enabling the reuse of nearly every part of the battery cell without requiring the expensive, inefficient and environmentally challenging processes used in conventional cell recycling. These cost savings are further optimized by our streamlined SemiSolid technology, which eliminates half of the steps used in conventional cell production", he added.

Mihai - Cristian Ioniță

Mihai - Cristian Ioniță

Any thoughts?