Concrete is responsible for 8% of the global CO2 emissions, and with production quantities expected to grow from 4.4 billion tons per year to 5.5 billion tons by 2050, companies are seeking to replace this polluting construction material with alternatives that are greener, but at least as durable in order to reduce the environmental footprint.

According to Arch Daily, one of those companies is Iberdrola, a Spanish company who works in the energy sector and that has over 1.2 million kilometers of electric transmission and distribution power lines.

As it wants to expand its electricity network, the company aims to get help from Hyperion Robotics, a Finland-based construction company, and Peikko Group, a Finnish supplier, in order to use 3D printing technology, which should help to improve the construction of its future networks.

Construction is one of the least automated industries, and the shortage of skilled workforce could have negative effects on companies that want to expand their business, but Hyperion Robotics wants to solve this issue through their 3D printed materials, which should boost efficiency and speed up the process of building.

Large-scale 3D printing of low-carbon concrete means that the process will be cheaper, faster, safer and more environmentally friendly as well.

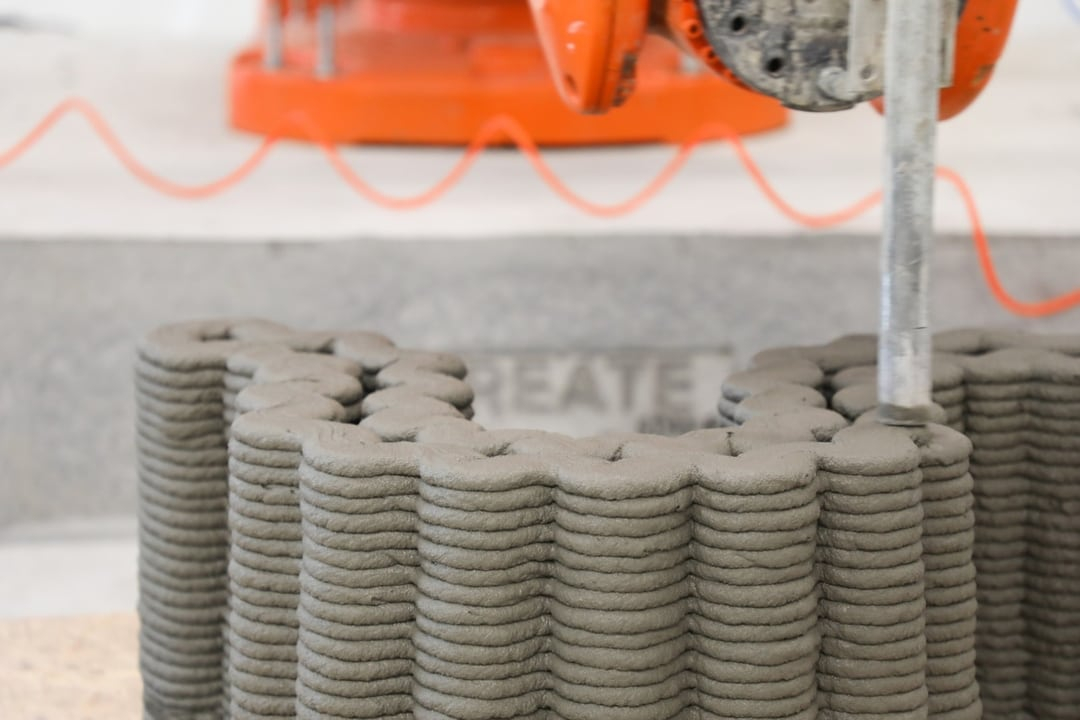

Through the process, Hyperion Robotics not only makes sure that less concrete is being used for construction, up to 75% less, which reduces the environmental footprint, but also that the robots are the ones doing the hard work, while workers only supervise the process.

The low-carbon concrete used by the company is made with end-of-life materials, such as mining tailings and demolition waste, which not only reduce the cost, but also help reducing about 90% of embodied CO2 emissions.

The first 3D printed pad in the world has been laid down by the three companies and it is one of the many foundations that Hyperion wants to build for the electric industry.

Henry Unterreiner, co-founder at Hyperion Robotics, said that "this [3d printed] foundation is very special. It has been designed, engineered, and printed with the help of Peikko and Iberdrola. Being the first in the world – it is saving 75% of the material – compared to traditional pad foundation, which you can typically find in energy infrastructures or any other type of projects.”

Concrete 3D printing is a process which reduces CO2 emissions and also simplifies the process of building concrete, and Hyperion aims to scale the process up in order to apply it to the energy infrastructure, hoping to reduce the environmental impact of these projects and reduce their cost and time of building.

Photo Source: Hyperion Robotics

Mihai - Cristian Ioniță

Mihai - Cristian Ioniță

Any thoughts?